Meet Creo Tool Design, what you Need to Capitalize on Global Manufacturing Excellence

Download a 30-day Trial of Creo 7.0!

By form submission, you agree to the Terms of Service

ABOUT

Creo Tool Design:

Create Complex Molds and Casts with Ease!

Plastic part design is the process and skill of balancing the unique material properties of plastic and the demands of molding with the characteristics and requirements of the product being designed. Industry has made eager use of this lightweight, moldable material to cut manufacturing costs, improve consumer appeal, and reduce everything from the usage of scarce natural resources to the number of dings on the driver-side door.

Plastic can be difficult and time-consuming to work with – as anyone knows who’s been faced with a bad mold or the results of a seemingly haphazard injection process. That’s why Creo Parametric has core 3D CAD capabilities in plastic part design and molding so you can make the most of plastic’s creative potential and get your part right the first time.

A well-designed mold can produce accurate uniform parts consistently with fast cycle time, ultimately keeping manufacturing costs down, revenue up and throughput high. It’s a durable and potent source of competitive advantage. Put Creo Tool Design to work for you.

-

COMPLEX TOOLING QUICKLY

COMPLEX TOOLING QUICKLY

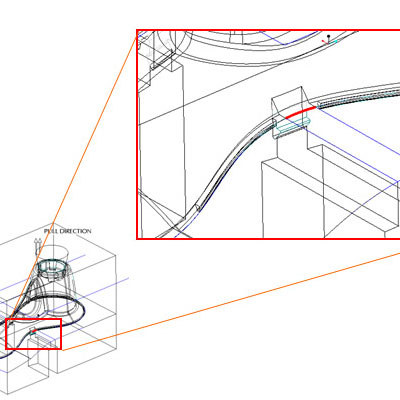

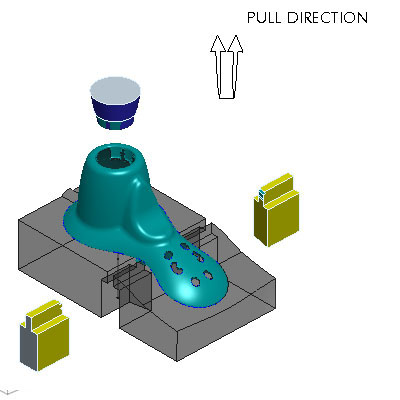

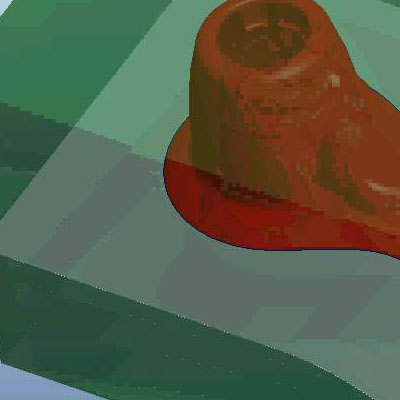

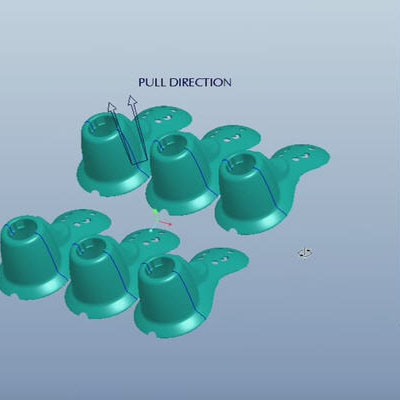

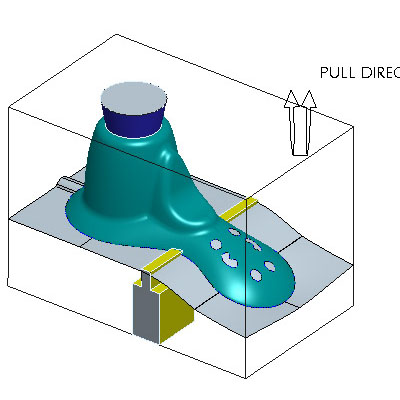

Evaluate mold draft, undercut and thickness problems, and then automatically create parting surface and splitting geometry in a process-driven environment that’s simple–even for the occasional user–who needs to create complex tooling quickly.

-

LESS REWORK

LESS REWORK

Even the occasional user can create single-cavity and multi-cavity molds and casts with ease. How? This extension steps you through the process, giving feedback and advice on the design. That’s less rework and redesign for you and a quicker, cheaper path to successful design of complex tooling.

-

WELL DOCUMENTED

Features

Creo Tool Design - Core & Cavity Design

Images & Videos

Design Examples Using Creo Tool Design

Select Category

-

Integral Solution

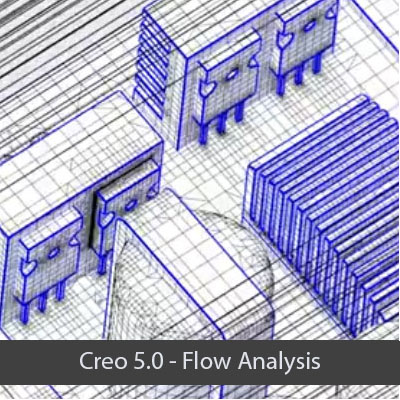

Integral SolutionIntegral CAD/CAM solution from conceptual design to manufacturing.

-

Lower Costs

Lower CostsEliminate costly rework via interference checking and mold opening simulation.

-

Automatic Updating

Automatic UpdatingAutomatic updating of tooling models, drawings and electrodes.

-

Evaluate Problems

Evaluate ProblemsEvaluate mold draft, undercut and thickness problems.

-

Create Molds

Create MoldsCreating single and multiple-cavity molds and casts.

-

-

-

-

-

See More Videos on Creo Tool Design